The pipe valve fitting industry—often abbreviated as PVF—is on the brink of major transformation. As technology evolves and new challenges emerge across industrial, municipal, and commercial sectors, staying ahead of the curve is critical. Whether you’re a contractor, engineer, or supplier, understanding where the PVF market is headed can help future-proof your projects and improve system reliability.

At Great Western Pipe, we’ve proudly served the Rocky Mountain region for over 70 years, offering a wide inventory of pipe, valve, and fitting products to keep your operation moving. In this post, we’ll explore some of the key trends shaping the future of the pipe valve fitting industry in 2025 and beyond.

1. Smart Technologies Are Redefining PVF Systems

The rise of IoT (Internet of Things) is now influencing even the most traditional systems. Smart pipe valve fitting components—such as digital actuators, pressure sensors, and connected valves—are increasingly being used in industrial automation, water treatment, and oil & gas.

These components allow for remote monitoring, automated pressure adjustments, and predictive maintenance, helping companies reduce unplanned downtime and boost system efficiency. In 2025, expect to see greater demand for these intelligent systems as businesses prioritize data-driven infrastructure.

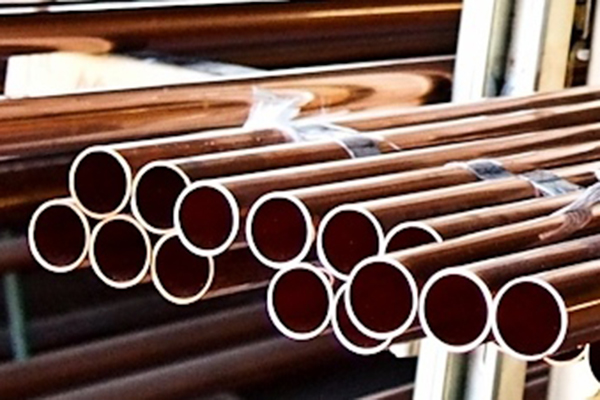

2. Material Innovation is Advancing Durability and Safety

Material science continues to push boundaries. New alloys, thermoplastics, and composite materials are offering higher corrosion resistance, improved pressure ratings, and longer lifespans for pipe valve fitting assemblies.

For example, high-density polyethylene (HDPE) and cross-linked polyethylene (PEX) are gaining popularity in municipal water systems, while stainless steel remains a top choice for hygienic applications. At Great Western Pipe, our partnerships with leading manufacturers ensure access to high-quality materials for every specification.

3. Sustainability is Driving Change in the PVF Sector

Environmental concerns are shifting the way we think about infrastructure. Pipe valve fitting products now need to support sustainable practices, from manufacturing to end-of-life recycling. The move toward low-emission materials, energy-efficient flow control, and leak-proof fittings aligns with both regulatory pressures and client demand.

Contractors and municipalities alike are seeking ways to reduce water loss, prevent emissions, and improve system longevity. Smart fitting solutions and durable, eco-conscious pipe materials are critical to achieving those goals.

4. Supply Chain Resilience & Digital Tools Matter More Than Ever

Over the past few years, supply chain disruptions and shifting market trends have underscored the need for trusted local partners. Having a reliable source for pipe valve fitting products—especially when timelines are tight—can make or break a project.

Great Western Pipe has built its reputation on maintaining a large in-stock inventory and providing fast delivery throughout Colorado and the surrounding region. We also support customers with digital tools, custom fabrication capabilities, and vendor-managed inventory systems to keep operations efficient.

5. Modular & Prefabricated Solutions Are on the Rise

As labor shortages and fast-paced construction timelines persist, prefabricated and modular pipe valve fitting systems are gaining popularity. These systems reduce on-site labor needs and installation errors while speeding up project timelines.

Prefabricated skids, spool assemblies, and custom valve configurations are now used in a wide variety of industries—including HVAC, chemical processing, and food manufacturing. Great Western Pipe works with project teams to help specify and deliver custom assemblies tailored to your needs.

Looking Ahead: Stay Ahead with the Right PVF Partner

The pipe valve fitting landscape is evolving rapidly. From digital valve integration to more sustainable materials, these changes open the door to safer, more efficient infrastructure projects. The key is having a partner who understands these shifts and can provide both the products and the guidance needed to navigate them.

At Great Western Pipe, we’ve supported projects of every scale with an unmatched inventory, decades of industry knowledge, and a commitment to customer-first service. Whether you’re planning a major municipal upgrade or managing day-to-day industrial maintenance, we’re here to help you find the right pipe valve fitting solution—every time.

Great Western Pipe & Supply Co.

Great Western Pipe & Supply Co.