Choosing the right type of pipe is a fundamental aspect of any construction, plumbing, or DIY project. The material you choose can significantly impact the functionality and longevity of the installed system. This article compares four pipe materials: steel, copper, plastic, and stainless steel, to help you decide for your project.

Steel Pipe

Steel pipes are known for their strength and durability, making them a preferred choice for commercial and industrial applications. They are highly resistant to shock and vibration, which makes them ideal for underground or external use. However, steel is prone to corrosion over time, which might require additional maintenance or protective coatings.

Advantages:

Strength: Steel is incredibly strong and can withstand high pressures and mechanical stresses.

Durability: With the correct protective coating, steel can last a long time even under harsh conditions.

Shock and Vibration Resistance: Ideal for applications where the pipes may be subjected to shock and vibration.

High-Temperature Tolerance: They can handle higher temperatures without losing their structural integrity.

Recyclable: Steel is a recyclable material which is beneficial for environmentally-conscious projects.

Disadvantages:

Corrosion: Without proper protective coatings or treatment, steel pipes are prone to corrosion over time.

Weight: The heaviness of steel pipes can make them challenging to handle and install.

Cost: Often more expensive than plastic pipes and may require more expensive equipment to install and maintain.

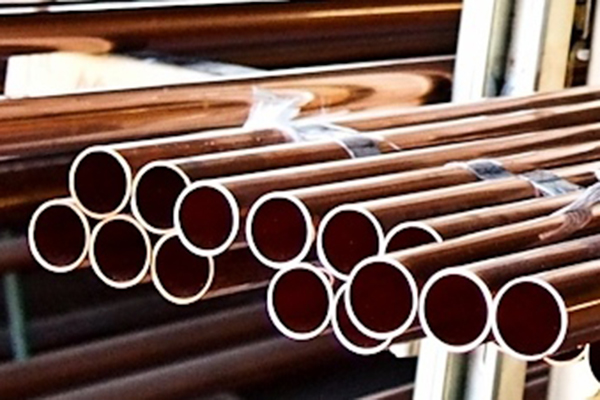

Copper Pipe

Copper pipes have been a staple in the plumbing industry for decades. They are known for their excellent corrosion resistance and ability to withstand high temperatures. Copper pipes are a suitable choice for both hot and cold water supply lines. They are also relatively lightweight and can be bent to a certain extent, allowing for easier installation.

Advantages:

Advantages:

Corrosion-Resistant: Copper resists corrosion and is suitable for underground installation.

Temperature Tolerance: They handle hot and cold water well, maintaining integrity under a wide temperature range.

Long Lifespan: With proper installation and maintenance, copper pipes can last for decades.

Microbial Resistant: Copper possesses antimicrobial properties, which helps in keeping water supplies clean.

Recyclable: Like steel, copper is also recyclable, making it a more eco-friendly option.

Disadvantages:

Cost: Copper is more expensive than plastic.

Skill Required for Installation: Installation usually requires soldering, which requires a skilled technician.

Potential Pinhole Leaks: Over time, copper may develop pinhole leaks which can be a hassle to repair.

Plastic Pipe

Plastic pipes, including PVC and PEX, are becoming increasingly popular due to their flexibility, corrosion resistance, and ease of installation. People often use them for residential water supply lines, drainage systems, and underfloor heating systems. Plastic pipes are also a cost-effective choice compared to metal pipes.

Advantages:

Cost-Effective: Plastic pipes are generally cheaper and are a budget-friendly choice.

Corrosion Resistant: They do not corrode, making them ideal for a variety of applications.

Easy Installation: Lighter in weight and easier to cut, join, and install compared to metal.

Flexibility: Some plastics like PEX are very flexible and can be maneuvered around obstacles.

Low Maintenance: They require less maintenance over time as they are resistant to corrosion.

Disadvantages:

Temperature Sensitivity: Plastic can warp or melt under high temperatures.

Strength: They are not as strong or durable as metal, especially in high-pressure situations.

Potential Chemical Leaching: Certain types of plastic may leach chemicals into the water over time.

Stainless Steel Pipe

Stainless steel pipes combine the strength of steel with the corrosion resistance of stainless material. They are a great choice for areas prone to corrosion and are often used in industrial and high-salinity areas. Stainless steel is also aesthetically pleasing, making them a preferred choice for visible plumbing systems.

Advantages:

Corrosion Resistant: Stainless steel’s resistance to corrosion is one of its most significant advantages, especially in high-salinity or corrosive environments.

Strength: Strong and durable, able to withstand high pressures and mechanical stress.

Aesthetically Pleasing: The sleek look of stainless steel can be more aesthetically pleasing, making them a preferred choice for visible plumbing systems.

Longevity: With proper care, stainless steel pipes can last a long time without losing functionality.

Disadvantages:

Cost: Stainless steel pipes are among the most expensive due to their many advantages.

Installation Difficulty: Installation can be challenging and usually requires professional welding for joining.

Weight: While not as heavy as regular steel, they are still heavier than plastic or copper, which can pose challenges during installation.

By understanding these pros and cons, you can make a better-informed decision based on your project’s specific needs, whether it’s plumbing, construction, or other types of installations.

When choosing pipes for your project, take into account the type of project, your budget, and the installation environment. Each material has its set of advantages and disadvantages that should be considered to ensure the success and longevity of your project.

Great Western Pipe & Supply Co.

Great Western Pipe & Supply Co.